Internal Combustion Engines Laboratory

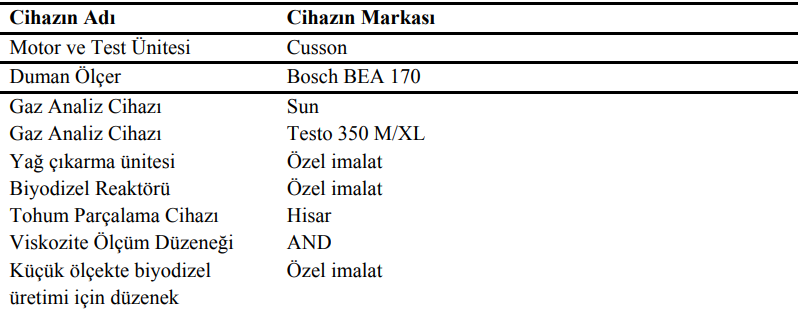

The devices in the Internal Combustion Engines laboratory are given in Table 1.

Table 1: Equipment in the Internal Combustion Engine Laboratory

Performance and emission measurements are performed on a diesel engine in the engine test unit shown in Figure 1. This unit is used in the application of related undergraduate courses, but students can also use this unit under supervision in applied projects within the scope of project courses. Soot measurement (Figure 2) and gas analysis (Figures 3 and 4) can be performed.

Figure 1: Motor Test Unit

Figure 2: Smoke Meter

Figure 3: Gas Analyzer

Figure 4: Testo 350 M/XL gas analyzer

In addition, the seed crushing device (Figure 5), oil extraction unit (Figure 6) and biodiesel reactor (Figure 7) used in alternative fuel production studies can be used in undergraduate project courses. Temperature dependent dynamic viscosities of liquids can be measured with the setup shown in Figure 8.

Figure 5: Seed Shredder

Figure 6: Oil extraction unit

Figure 7: Biodiesel Reactor

Figure 8: Viscosity Measurement Setup

Small scale biodiesel production can be carried out in the setup shown in Figure 9. These productions are also introduced to undergraduate students within the scope of project courses.

Figure 9: Setup for small-scale biodiesel production (Water cooler, three-throat flask, recooler, magnetic stirring heater, solutions prepared for free fatty acidity measurement and centrifuge)