STONE CUTTING WORKSHOP

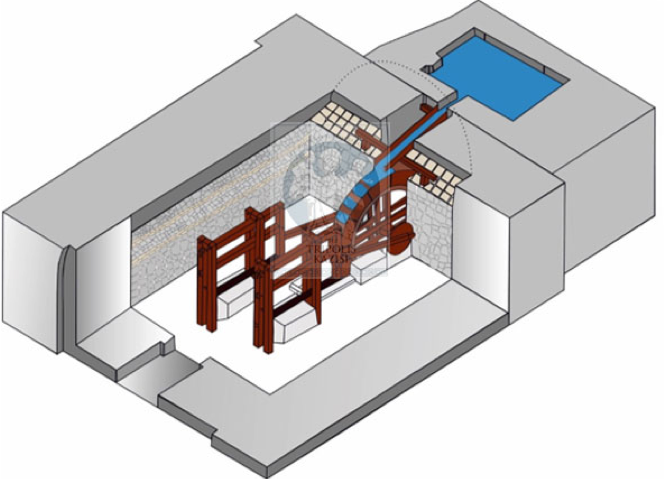

Uncovered in the 2022 season, the stone cutting workshop operated on an area of approximately 80 m2 in two rectangular spaces. The working principle of the workshop consists of a stone cutter activated by water power. A crank was üşed to convert the circular motion generated by the rotation of a wooden wheel with a diameter of about 2.5 m into a horizontal thrust. The approximately 1 kW of power generated by the pushing arm connected to the crank was directed to a sawmill that cut with a toothless iron saw. The saw was suspended from a rectangular wooden frame, which was secured by four ropes with stone counterweights at the ends. This allowed the saw to move back and forth, cutting a 1 m 2 piece of stone in about 20 hours.

The cutting work on the katrak (Stone saw) was carried out with a constant supply of water and quartz sand. it is understood that this workshop, which was actively üşed in the 6th- 7th century AD, specialized in the production of triangular, quadrangular, hexagonal and decagonal shaped paving stones made of marble or travertine by cutting the architectural blocks of large public buildings of the Roman Period, which were out of use for various reasons.

In one of the two 50 m 2 rectangular rooms, the cutting of large or small blocks was carried out, while in the adjoining room the small marble or travertine slabs were given their final shape by the stone sawing machine.