1-) Thermoelectric Heat Pump Design, Optimization and Automatic Control for Premature Baby Incubators

In the research, in order to eliminate hyperthermia & hypothermia problems experienced in premature baby incubator systems due to various factors with a single device and the problems experienced in temperature distribution and control in existing resistance incubator systems, a modern, technological baby incubator operating with a thermoelectric heat pump has been developed. Moreover, the thermoelectric modules and the heatsinks on the modules were optimized according to the desired heating power from the incubator for the developed thermoelectric heat pump. In addition, in order for the developed device to be controlled automatically, the PID coefficients that control the system were determined precisely by using Matlab / Simulink® software. The prototype of the developed system within the scope of the research was manufactured and the thermal and hydraulic performances of the heat pump system with a commercial resistance incubator were investigated and compared by preliminary tests. According to the results, it was determined that the developed system can eliminate the problems experienced in existing (resistance) systems and control the temperature more precisely (0.05 ºC) and homogeneously compared to the resistance system. Since baby incubators are generally used in the heating mode, it has been determined that the efficiency of the system having thermoelectric heat pump is higher than the system operating with resistance. In addition to all these, it has been determined that, thanks to the cooling mode of the developed thermoelectric system, it can run smoothly when the ambient temperature is high, and it can be used in all incubators (fixed, transport and even idle incubator) as the thermoelectric system has been developed modularly [1].

2-) Commercial Evaporative Cooling System having Thermoelectric Cooler Cabinet

In the research, a new device design and prototype production that incorporates evaporative cooling techniques and thermoelectric cooling principles has been created. The important parameters of the prototype device such as air flow rate, air inlet-outlet temperatures and humidity values were determined in the test room which was built in accordance with the TS EN ISO 23953-2 standard and whose infrastructure is located in Alindair Cooling Systems Industry in Denizli. Tests of the device were carried out in the test room and the mechanical, thermal and hydraulic performances of the design were determined with the thermoelectric performance analysis system (TEPAS) device. The upper part of the commercial evaporative cooler was chosen as the location and a small isolated volume was created in this area. Utilizing the cold surface of the thermoelectric module, this insulated small volume is cooled. The heat generated on the other surface (hot surface) of the thermoelectric module was experimentally investigated with 3 different prototypes developed within the scope of the research according to the location and mechanism of the heat removal. As a results, it was determined that the water cooling prototype developed by using the water circulation in the evaporative cooling system performed the best performance and so, that prototype was commercialized. With the newly developed design, both the ambient environment is cooled with evaporative cooling techniques and various food and beverages placed in the insulated small volume created with the thermoelectric system can be easily cooled [2].

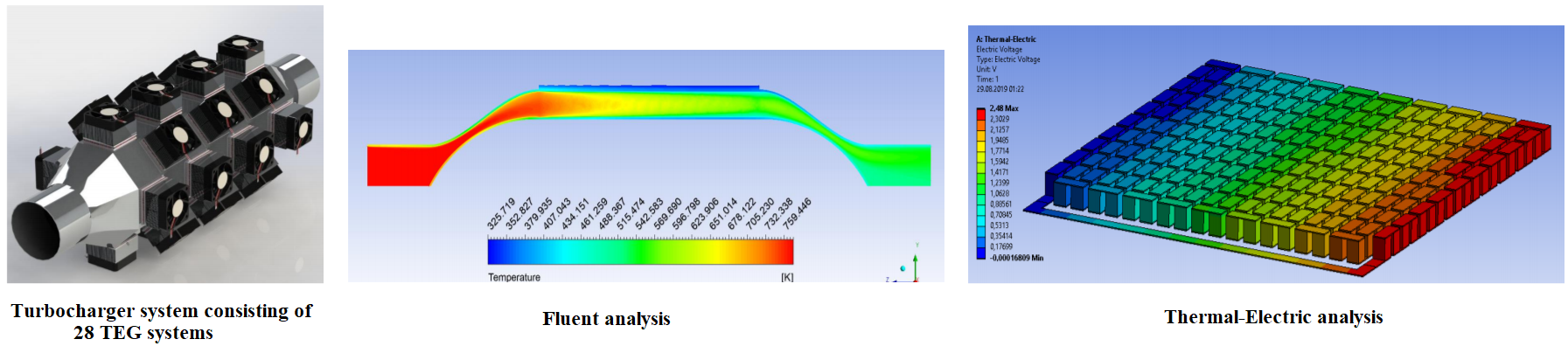

3-) Electrical Power Recovery from Exhaust Heat Energy with Thermoelectric Generator Modules

In the research, a thermoelectric generator modules (TEG) system was placed between the compressor and the intercooler in the turbocharger systems, and it was aimed to obtain electrical power by utilizing the heat energy to be discharged from the intercoolers. The most suitable system was designed by performing numerical analysis of the TEG system for different external ambient temperatures and different sizes of pellet. Simulations in numerical analysis were carried out using ANSYS Fluent and Thermal-Electric programs. Also, the analysis results of a commercial module (TGM-199-1.4-2.0) were compared with the numerical results. According to the results, it was determined that the total power value obtained from the TEJ system consisting of 28 TGM-199-1.6-2.0 modules was 70.95 W and the current value was 22.71 A, when the dimensionless electrical resistance was 1.25 and the external ambient temperature was 268 K [3].

References

[1] Yeler, O., "Design, development and determination of thermal-hydraulic characteristics of preamature baby incubator having thermoelectric heat pump", Dissertation, Institute of Science, Pamukkale University, 2020.

[2] Gündüz, A., "Investigation of thermal and hydraulic performance of evaporative cooler with thermoelectric cooling cabinet", Master Thesis, Institute of Science, Pamukkale University, 2019.

[3] Gürcan, A., "Recovery of exhaust heat energy using thermoelectric generators in different sizes", Master Thesis, Institute of Science, Pamukkale University, 2019.